Why Lithium-Iron Phosphate Batteries

Are the Future of Ice Resurfacing

Why Lithium-Iron Phosphate

Batteries Are the Future of Ice Resurfacing

At WM technics, we placed our bets

on the electric drive with lithium-iron phosphate

batteries for our ice resurfacing machines. This is due

to the good odds: our ice resurfacers are “born

electric”, meaning we have designed them as electric

vehicles right from the start. Also, we are certified

battery assemblers and won’t work with anything less

than state-of-the-art technology – and that’s what

lithium-iron phosphate batteries actually are.

E-mobility is a pretty young market prone to constant

change, innovation, and paradigm shifts.

So is also the ice resurfacing

business. Which batteries are being used? And why does

WM technics bet on lithium-iron phosphate batteries? So

many FAQs – we have the answers.

On which kind of motors do ice

resurfacing machines run?

What are the benefits and

disadvantages of the different kinds of batteries

(lead-acid, lead-gel, lithium-iron phosphate)?

On Which Kind of Motors Do Ice

Resurfacing Machines Run?

The whole topic is complicated, so

our answers cannot be too detailed. That is why we are

breaking everything down here into 2 different types of

drive.

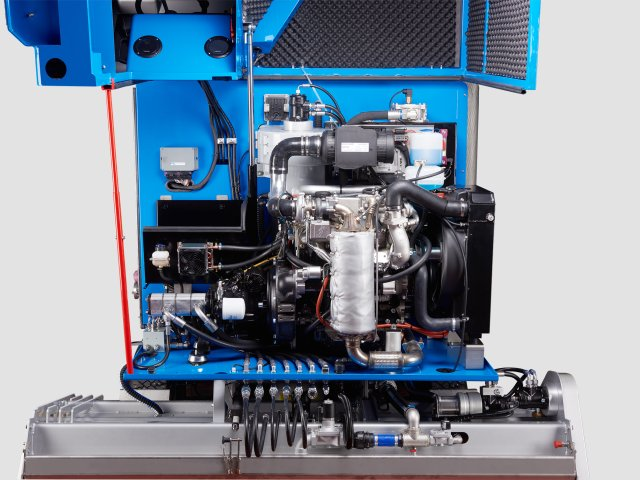

1. Combustion Engines

a. Fuel or gasoline

The good, old combustion engine

driven by fuel or gasoline is still a thing in ice

resurfacing. But the signs are clear: there won’t flow

much water down the river until the market turns fully

electrical. That is happening for pretty good reasons:

combustion engines are deafening, emit polluting exhaust

gases, and will one day no longer be affordable as oil

reserves dwindle. But we will still turn the corner

before the last oil reserve has been drained dry: even

the automotive industry is gradually accepting the

change to -mobility.

b. Natural Gas (LPG)

LPG engines are actually combustion

engines and dominate the ice rinks in the United States.

And there are good reasons for that: the US has high gas

reserves; therefore, the stock and reasonable prices are

secured for a long time. However, the states are

perceiving the wind of change, not least because of the

recent European shortage of natural gas, and its

implicit consequences have not gone unnoticed overseas.

Even the last person in the States has come to the

conclusion that natural gas is a finite resource and

that e-mobility has become a central aspect of future

mobility scenarios.

2. E-drive with batteries

a. Lead-Acid & Lead-Gel Batteries

(Pb/AGM)

Lead acid and lead gel batteries

are iconic of the rapid development that e-mobility has

taken in just a few years, especially in the logistics

sector (forklift): Just as they have become standard in

ice resurfacers, they are already a phase-out product

for the industry. Lithium-based batteries are slowly but

surely overtaking them. Why? We will explain that later.

b. Lithium-Iron Phosphate Batteries

(LiFePO4)

WM technics doesn’t cope with

phase-out products. When we develop new technologies, we

only work with state-of-the-art - that means in terms of

battery-powered e-drive in ice resurfacing machines with

lithium-iron phosphate batteries. High cycle stability

is only one of the advantages; all lithium technologies

have in common: no combustion gases, no unpleasant

odors, and no noise.

Born Electric

That is why we devote ourselves to

the “born electric” principle: our ice resurfacers have

been thought, designed, planned, and built as electric

machines equipped with in-house assembled batteries.

What Are the Benefits and

Disadvantages of the Different Kinds of Batteries

(Lead-Acid, Lead-Gel, Lithium-Iron Phosphate)?

Get here a short overview of the

benefits and disadvantages of the different battery

kinds:

1. Lithium-Iron Phosphate (LiFePO4)

Benefits:

Lifetime: at least 3-4 times as

many charge cycles as lead batteries

Weight: weight reduced by 75%

compared to lead batteries

Efficiency: only 1-2 kWh per ice

treatment

Performance: high discharge power

and extremely high peak power

Charging time: extremely fast

charging with a fast charging terminal (80 % in 60

minutes)

Maintenance: maintenance free

Energy density: high energy density

- one small battery is sufficient

Temperature range: -45 °C to 85 °C

(recommended: -25 °C to 55 °C)

Fast payback: due to less

maintenance, high efficiency in consumption, longevity

Cost/benefit: cost-intensive

purchase/long lifetime

Security: Due to their cell

chemistry, LiFePO4 cells are

considered to be intrinsically safe as they eliminate

the risk of thermal runaway and membrane melting which

can occur in other lithium-ion accumulators. Operator

safety is enhanced as no toxic gases are emitted while

charging.

Disadvantages:

Acquisition cost: about 2-3 times

more expensive than lead-acid batteries with the same

capacity

Charge balancing: battery

management system (BMS) necessary

2. Lead-Acid Batteries/Pb

Benefits:

Reliability: the most reliable of

all batteries

Lifetime:

up to 1,800 charging

cycles

Maintenance: individual cells

replaceable with commercially available parts

Cost/benefit: inexpensive purchase

Disadvantages:

Maintenance 1: water level

maintenance once a week

Maintenance 2: annual all-around

maintenance of approx. 120 minutes

Odor: gas or sulfur odor (formation

of oxyhydrogen gas);

Corrosion:

accelerator in case of poor ventilation

Infrastructure: garage with

ventilation necessary

Charge: constant charge necessary

Charging time: 6-7 hours with

qualitative charging

Efficiency: poor

3. Lead-Gel Batteries/AGM

Benefits:

Maintenance:

low-maintenance/maintenance-free

Features: sealed cells with gel

carrier without liquid acid

Infrastructure: no special garage

is required

Disadvantages:

Acquisition cost: 1.5-1.7 times

more expensive than Pb

Cost/benefit: medium

acquisition/less power density

Efficiency: poor, high internal

resistance and therefore relatively low power output